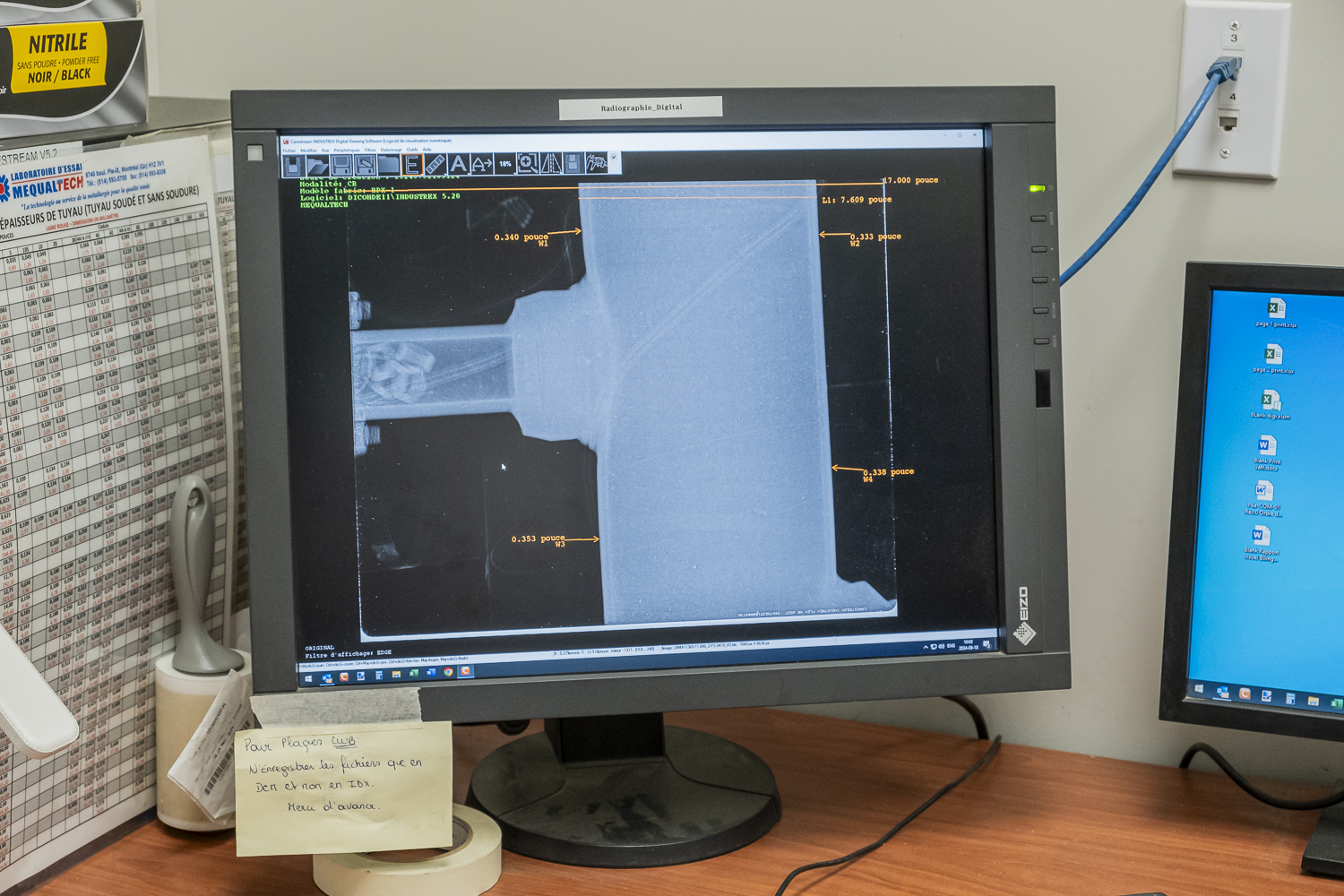

Other Inspections

As a leader in both destructive and non-destructive testing in Quebec, Mequaltech offers a full range of inspection and testing services. Explore our additional inspection techniques, tailored to meet the specific needs of each project.